Tampieri green energy produces electrical and thermoelectric energy from renewable sources. It runs one of the largest solid biomass plants in Italy, capable of generating about 90,000,000 KWh of electricity per year.

This is partly used to power the industrial plants of the Tampieri Group, which are completely energy self-sufficient, while the surplus is fed into the national grid.

Ideal partners of Tampieri green energy are:

the agro-food industry which sells the by-products of its production processes

the farms which invest in crops for energy-supply purposes and the like

In the field of energy production Tampieri green energy has been foresighted enough as to tap to its own biomass. Indeed, it turns the residues and by-products from the oil mill production process into fuel. These are natural resources that, instead of being disposed of, are reused to generate green energy. The protection of the environment and the economic growth of the Faenza area have always been behind our investments.

We invest in systems which are often designed in-house and combine high technology and eco-sustainability.

For example, among the new technologies introduced by Tampieri green energy, the steam generator and the air-cooled condensers allow us to consume far less energy, while saving water resources. This is an issue that cannot be overlooked any longer.

Investments are also made to control and reduce emissions, which are monitored 24 hours a day in our operations centre and reported daily to the Environment and Energy Agency (ARPAE) in Ravenna.

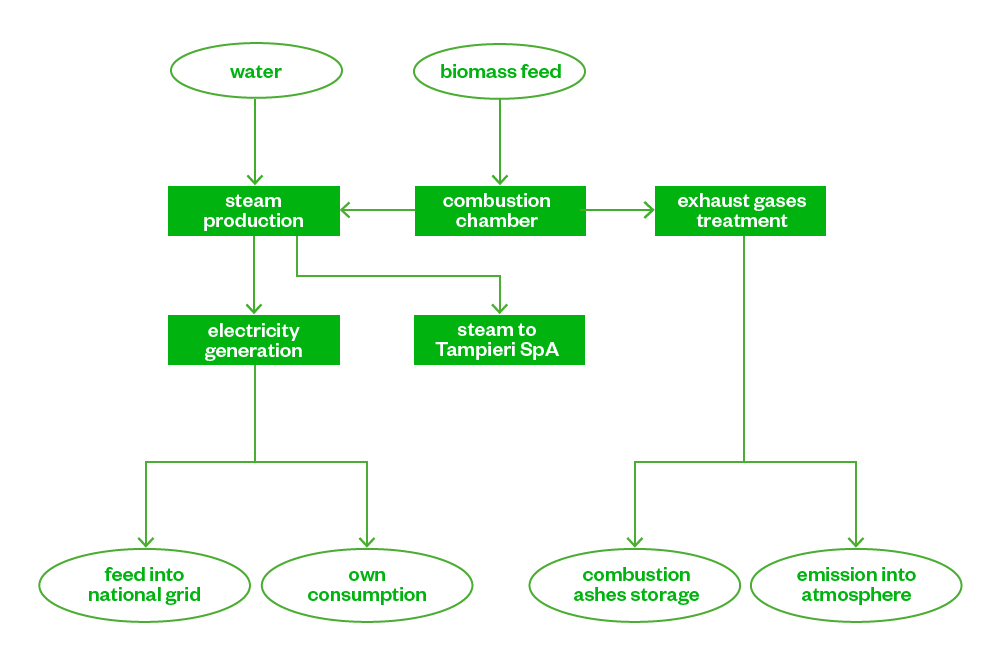

Tampieri green energy's generating plant is based on

a boiler/steam turbine cycle, with a boiler powered by solid biomass and one turbine of nominal electrical power equal to 20 MW.

In the steam boiler/turbine cycle, biomass is burned to produce high pressure steam, which is expanded in the turbine producing mechanical energy; the turbine is coupled to an alternator which converts mechanical energy into electrical energy.

Based on needs, a variable quantity of low pressure steam is drawn from the turbine and used in the Group's industrial processes. The boiler fumes are treated to reduce polluting substances before being released into the atmosphere.

Tampieri green energy (Tampieri energie srl) carries out its activity in compliance with ISO 14001. Any company which is issued this type of certification commits itself to reducing the waste of prime resources (energy, water, etc.) on a daily basis, by adopting corporate policies oriented towards transparency and the constant improvement of its environmental performance. The system is CSQA certified

What do you mean by solid biomass?

Solid biomass means a number a of biodegradable natural materials capable of generating electrical and thermal energy through combustion. The biomass Tampieri green energy burns is mostly made up of by-products and waste from the processing of corn, sunflower and grape seeds, as well as from wood and other natural materials. No plastic or urban waste is burnt. Exploiting biomass is beneficial for the environment, as it limits Co2 emissions in the air and dramatically reduces the use of polluting materials, such as oil, other inorganic substances and fossil fuels.

What comes out of the chimneys at Tampieri green energy?

What comes out of our chimneys are the fumes from the biomass combustion process, which are duly treated before being released into the atmosphere. The plant is equipped with systems for reducing dust and any other potentially harmful substance contained in it. A continuous monitoring apparatus fitted at the mouth of the chimney, just where the emissions are let out, guarantees and validates the effectiveness of these systems. Data are sent daily to the Environment and Energy Agency (ARPAE).

What uses do the ash from biomass combustion have?

Most of the combustion ash is reused by cement and brick factories, as well as to produce fertilizers. A minimum proportion, about 6 or 7%, is disposed of by law.